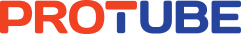

Metal sheets to handle ?

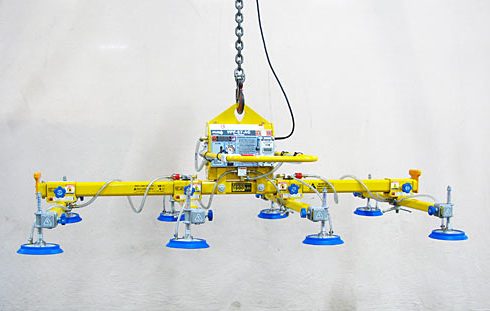

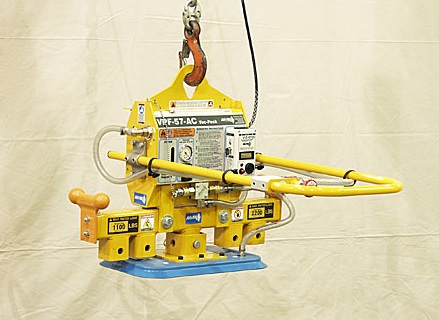

High vacuum suction devices are mostly used for applications requiring the handling of metal sheets. Unlike magnets, the use of vacuum as a gripping mode gives the flexibility to handle ferrous OR non-ferrous parts. The design also has the advantage of better spreading the support of the load along the parts to help reduce deflexion. The vacuum power pack is mounted directly on the unit which makes it easy to install. Hook, plug and play! The surface of the load needs to be non-porous, smooth and clean.

Technical Specifications

- Electrical, pneumatic, or mechanichal self-powered design options

- Integrated vacuum power pack

- Filter with view port to monitor for cleaning

- Vacuum gauge is mounted on front cover for continuous monitoring by operator

- Twistlock power cord plug and receptacle (electric model)

- The slide valve assembly allows vacuum grip and release and is mounted to the front handlebar for convenient access by the operator

- Safety lock to keep the slide valve in the grip position while lifting a load to prevent accidental load release

- Ergonomic adjustable front handlebar

- Vacuum reservoir with check valve to maintain vacuum if the supply of compressed air or electrical power is interrupted, for safe handling of non-porous load

- Each suction plate is adjustable on the cross beams and the cross beams are adjustable on the main beam

- The suction plates have an articulated suspension on all sides

- Vacuum leak sensor and warning device including battery. Consists of audible and visual warning signals (horn & red light). System is plumbed to the Vac-Pack and monitors vacuum level triggering the alarm in the event of a loss in vacuum level

- Parking stand offered in option (to support the lifter on the ground)

- 90 deg / 180 deg lifter with manual or powered tilt available