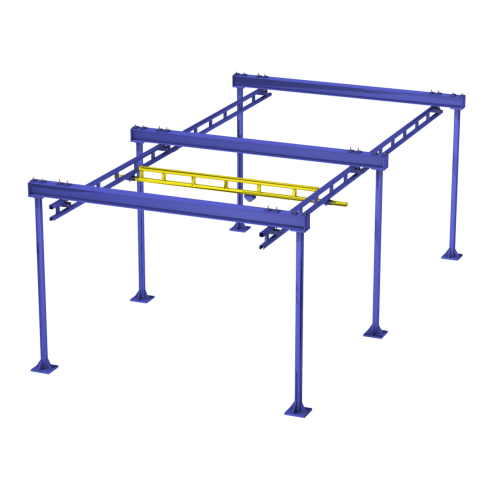

Prefer being supported directly on the floor ?

Free Standing floor supported systems do not put stress on the building’s overhead structure. Installation is usually more straightforward and these cranes are also easier to relocate in the future. Free standing systems require a reinforced concrete floor of at least 6 inches.

Technical Specifications

- Capacities from 150 to 4000 lbs

- Rectangular Coverage with up to 34’ bridge and 124’ runway standard

- Standard support distances of 20, 25, and 30 feet (columns c-c) allows reduction of the number of columns required

- Four distinct sizes of track - 250, 500, 1000 and 2000 - enables you to keep the weight and price low

- Floating end truck with horizontal wheels results in unmatched ease of positioning and movement. The bridge travels smoothly no matter where a load is positioned on the bridge.

Features and Benefits

- Enclosed track / easy movement and long life

- Rigid runways / superior load positioning – no movement or “crabwalking” of the bridge

- Easy to install / Install on any standard 6" concrete floor

- Smooth rolling surface / Easier movement of bridge and trolleys

- Taper runway profile helps to center the wheels in the track and prevents debris and dust from settling on the rolling surface

- Low track profile weight reduces operator push-pull forces

Options available

- Multiple bridges

- Aluminium, galvanised, SS304

- Telescopic bridge

- Motorization of the movement

- Custom painting, colors, FDA approved white paint

- Seismic design Zone IV

- Cantilevered supports

Brochure

Free Standing Bridge Crane Brochure (PDF) 3.12 Mo